Overview

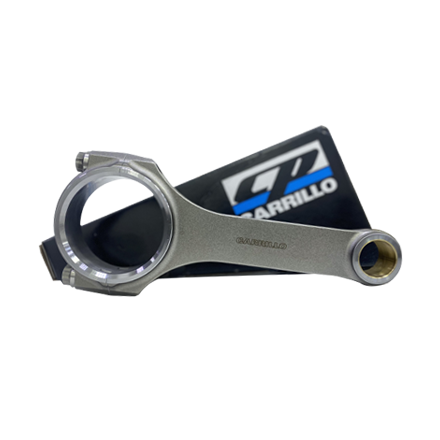

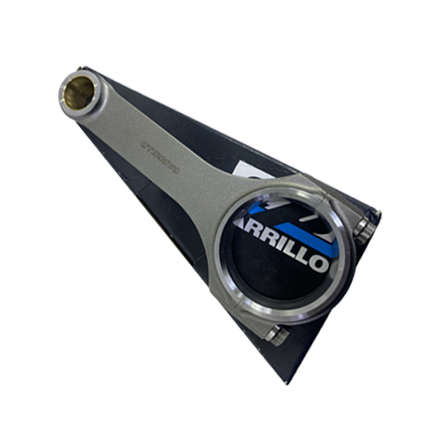

The CP-Carrillo TO-1FZFE-1>66063H Pro-H 3/8" connecting rod is a high-performance, race-ready component designed for the Toyota 1FZ-FE engine. It features a straight H-beam design forged from Carrilloy steel, a robust chrome-nickel-molybdenum-vanadium alloy produced with vacuum arc remelt for enhanced strength and fatigue resistance. With a center-to-center length of 6.063 inches, a big-end bore of 2.3830 inches, and a big-end width of 1.096 inches, this rod ensures an accurate fit for the crankshaft. The pin bore is 26 mm with a pin-end width of 1.096 inches, compatible with floating pin and high-performance piston setups. Equipped with 3/8-inch WMC multiphase bolts, it provides excellent preload and durability under extreme conditions. Weighing approximately 754 grams, the rod balances strength and high-RPM responsiveness. Manufactured in the USA, each rod undergoes CNC machining with probing verification, double magnaflux inspection, Rockwell hardness testing, and shot-peening to guarantee tight tolerances and structural integrity, making it ideal for off-road, overland, and high-output engine builds.

Features

- Straight H-beam design for superior strength and rigidity under high stress

- Forged from Carrilloy steel (chrome-nickel-molybdenum-vanadium alloy with vacuum arc remelt) for exceptional durability and fatigue resistance

- 6.063-inch center-to-center length, optimized for Toyota 1FZ-FE engines

- Big-end bore: 2.3830 inches (60.53 mm) and big-end width: 1.096 inches (27.84 mm) for precise crankshaft fit

- Pin bore: 26 mm and pin-end width: 1.096 inches (27.84 mm), compatible with floating pin and performance pistons

- 3/8-inch WMC multiphase bolts provide high preload and excellent fatigue strength

- Weight approx. 754 grams, balanced for durability and high-RPM responsiveness

- Manufactured in the USA with strict quality control in small batch production

- CNC machined with probing verification for tight dimensional tolerances